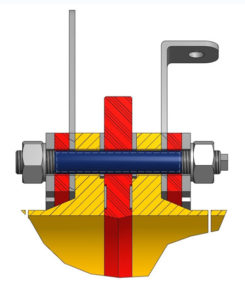

Insulating flange DIN, type HP2*

* (patented by Lannewehr + Thomsen GmbH & Co.KG)

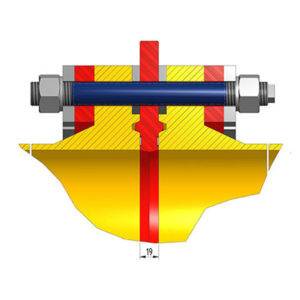

Insulating flange ASME, type HP2* for RTJ flanges

* (patented by Lannewehr + Thomsen GmbH & Co.KG)

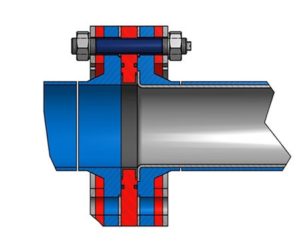

Insulating flange HP2* for water

* (patented by Lannewehr + Thomsen GmbH & Co.KG)

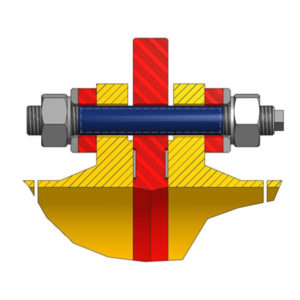

Insulating flange DIN, type HQ2

Insulating flange ASME, type HQ2 for RTJ flanges

Insulating flange DIN, type HQ2 for recessed flanges